The STINGER M Class Industrial Vacuum

Designed, developed, and manufactured in Ireland by Laserchaser

Built for the Toughest Dust on Site

Traditional industrial vacuums once relied on primary filter bags and could run for years with minimal issues. As bag costs increased, most manufacturers shifted to filter-vibration systems and complex electronics to keep filters clean.

But for applications like wall chasing, which produces up to 10 litres of microfine dust per hour, even the best brands struggle to cope.

Laserchaser has spent 25 years perfecting wall-chasing technology- and now we’ve built the vacuum designed specifically for it: the STINGER M Class.

The STINGER M Class Industrial Vacuum

Designed, developed, and manufactured in Ireland by Laserchaser

Built for the Toughest Dust on Site

Traditional industrial vacuums once relied on primary filter bags and could run for years with minimal issues. As bag costs increased, most manufacturers shifted to filter-vibration systems and complex electronics to keep filters clean.

But for applications like wall chasing, which produces up to 10 litres of microfine dust per hour, even the best brands struggle to cope.

Laserchaser has spent 25 years perfecting wall-chasing technology- and now we’ve built the vacuum designed specifically for it: the STINGER M Class.

The STINGER M Class Industrial Vacuum

Designed, developed, and manufactured in Ireland by Laserchaser

Built for the Toughest Dust on Site

Traditional industrial vacuums once relied on primary filter bags and could run for years with minimal issues. As bag costs increased, most manufacturers shifted to filter-vibration systems and complex electronics to keep filters clean.

But for applications like wall chasing, which produces up to 10 litres of microfine dust per hour, even the best brands struggle to cope.

Laserchaser has spent 25 years perfecting wall-chasing technology- and now we’ve built the vacuum designed specifically for it: the STINGER M Class.

Why the STINGER Is Different

Cyclone-Driven Dust Separation

Built-in cyclone separator captures 98% of dust before it reaches the chambers.

Dust is forced directly into the Primary Chamber for efficient collection.

Dual-Chamber System

Primary Chamber: Captures the first 98% of material.

Secondary Chamber: Collects the remaining 2% of microfine dust.

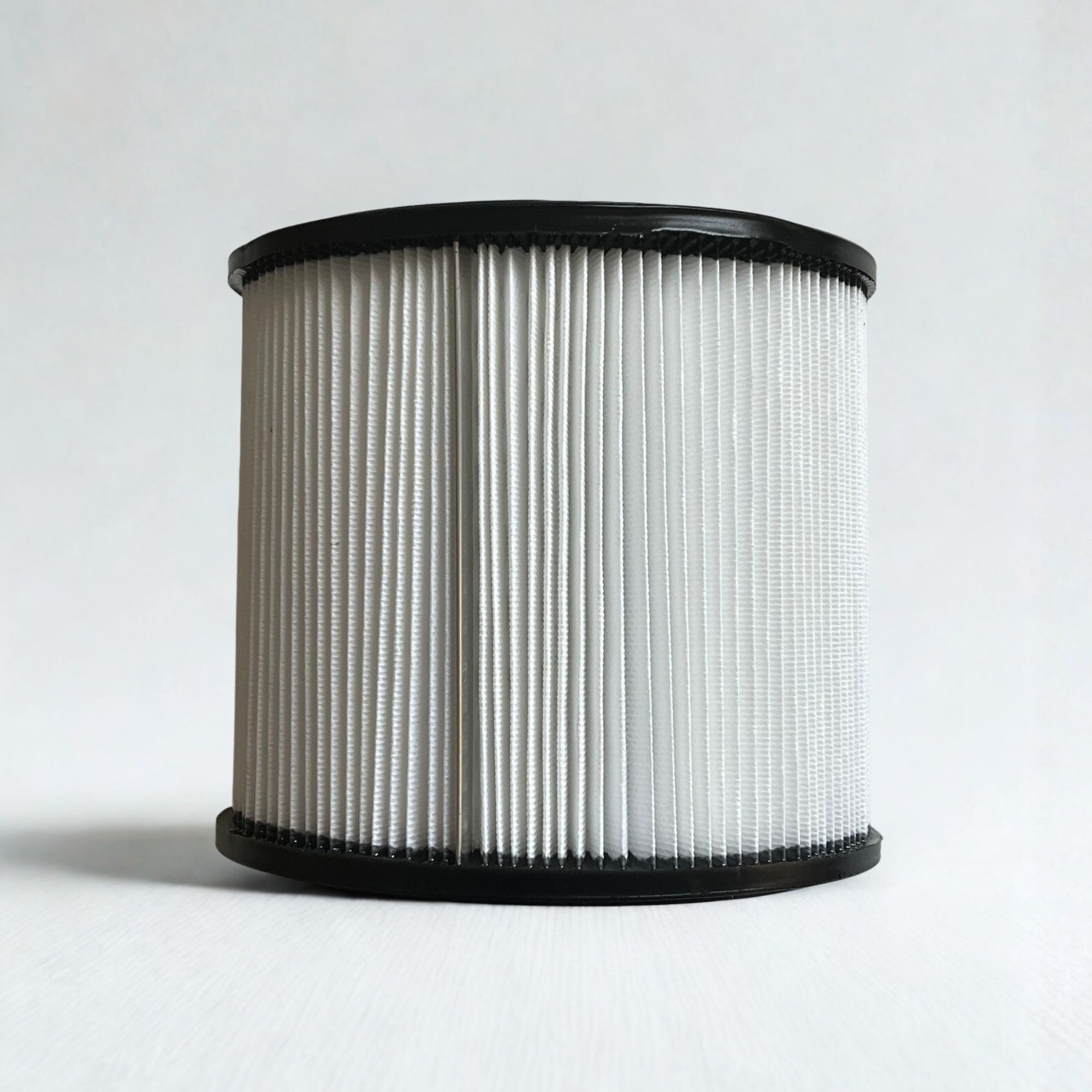

Clean Filter, All-Day Performance

A simple, low-cost fleece bag traps the last 2% before it ever reaches the motor filter.

The motor and filter sit in the Secondary Chamber, staying clean and operating at full strength all day—without clogging or downtime.

Engineered for Reliability

The STINGER eliminates the need for filter-vibration units and electronics, removing the biggest failure points found in most modern M Class vacuums. After 3 years of on-site testing, we refined it into a machine that is:

Simple by design — no electronics, just a motor and an on/off switch

Rugged and durable — no moving parts to break

Built for continuous operation — runs all day, every day

Economical to maintain — reusable fleece bag protects the filter

Easy to clean — standard motor filter can be washed in water